DFA Product Simplification

DFA Product Simplification software utilizes an intuitive question-and-answer interface that identifies opportunities for substantial cost reduction in a product. By applying industry-tested minimum part count criteria, the software finds parts that can be consolidated/eliminated while maintaining 100% functionality. The outcome of a DFA-based design is a more elegant product that is both functionally efficient and easy to assemble. DFA re-designs also have the added impact of increased quality and reliability, faster development time, and require fewer suppliers.

Benefits Of Using Design For Assembly Software

Estimate Difficulty Of Assembly

DFA establishes a rating for your product design in terms of its difficulty of assembly. The software rates each part according to how it is grasped, oriented and moved for insertion and to how it is inserted and/or fastened onto the product. By rule, products that are easy to assembly tend to cost less than assemblies that are difficult.

Support Decision Making

DFA software provides you with objective, consensus-building information so your team can examine all the potential design solutions and select the most effective approach. You can easily incorporate product input from other groups, such as field service and marketing.

Integrate Design and Manufacturing

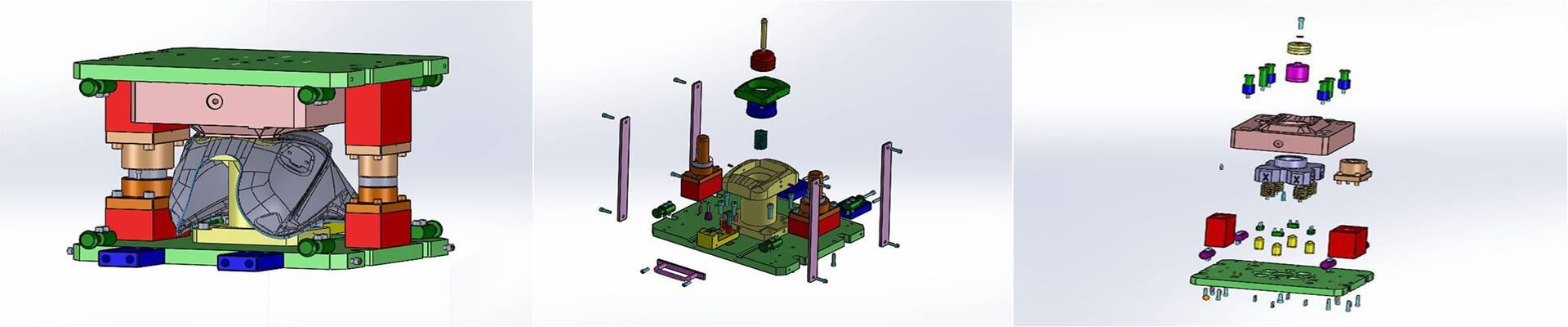

The DFA approach gives you an overall structure for making design changes in light of related material and manufacturing costs.

Used together, DFA and DFM enable engineers to select appropriate and cost-effective shape-forming processes for components.

Benchmark Existing Products

The DFA index, a measure of assembly efficiency, serves as a basis for quantitatively comparing design alternatives internally or against competing products. The software yields an objective measure that is independent of product size or complexity.

Design Reviews

DFA analysis can guide the progress of a design, verifying improvement as it evolves. As you eliminate redundant parts or operations and remove assembly difficulties, assembly efficiency scores noticeably improve.

Design Skills

The software helps designers establish the theoretical minimum number of parts for a product. In the process, engineers identify design concepts that reduce unnecessary complexity and cost.

The Link To Design For Manufacture

DFA complements Design for Manufacture (DFM). Engineers use DFA software to reduce the assembly cost of a product by consolidating parts into elegant and multifunctional designs. DFM software then allows the design engineer quickly to judge the cost of producing the new design and to compare it with the cost of producing the original assembly. Used together, DFM and DFA software gives engineers an early cost profile of product designs, providing a basis for planning and decision making.

Such analyses, when performed at the earliest stages of concept design, have the potential to greatly influence manufacturing and other life-cycle costs before the costs are locked in.

DFA Software Average Reductions

Results compiled from over 100 published case studies